A needle valve is a particular type of valve, one which has an small port and a needle shaped plunger that moves up & down within the confines of the port. In this way, it resembles a needle inside a syringe, which is how it gets its name. The plunger can be moved up and down within the port, allowing for more precise flow control.

Some valves only have two settings which are open and closed, but a needle valve might be half-open, barely open, or fully open creating the opportunity for greater precision.

How Do Needle Valves Work?

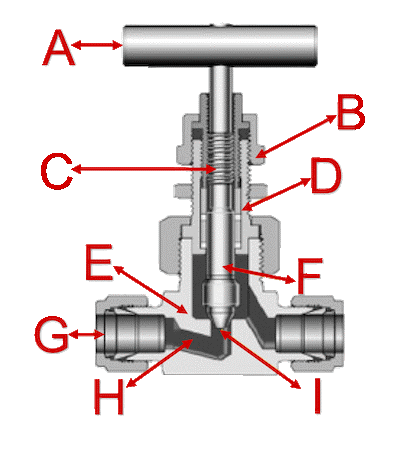

Needle valves open and close an orifice with a tapered end that raises and lowers with the spin of a handle. Below Figure shows a needle valve cross sectional view, design, and components. The handle (A) is connected to the plunger, also called a stem (F). When you turn the handle, the plunger moves up or down based on the threads (C). The locking nut (B) prevents it from fully unscrewing. As the plunger moves down, the tapered pointed end (I) comes into contact with the valve seat to fully seal the orifice (H). Often, the valve seat is also tapered. There are various options and sizes available to connect it to a pipe or hose through the port connection (G) on the input and output. The bonnet (D) is connected to the valve housing (E), which can be made out of different materials like stainless steel.

Where Are Needle Valves Used?

They are specifically useful in regulating precise flow and exact calibration in small channel applications.

– All field analog instruments are fitted with a needle valve to control flow entry, where sudden surges of fluid under pressure can damage the instruments.

– Needle valves can be used in situations where the flow must stop gradually and in the application where precise adjustments of flow are required or where a small flow rate is desired such as sample points in the piping

– Needle valves can be used as both on/off and throttle valves

– Used in all types of industries for controlling and metering applications of fluid such as steam, air, gas, oil, water, or other non-viscous liquids

Please see the product catalog for more about the needle valve. Should you have any questions, requirement, please contact FITOK Group authorized distributor in India A B process technologies directly & their sales and technical support will reach you soon.