Leak testing is crucial for the automobile industry, locating leaks is not only important in initial vehicle quality that is measured, reported, and marked but also to overall component lifecycle quality and longevity.

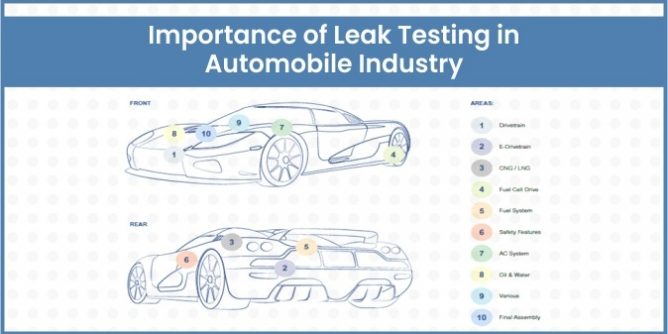

During the manufacturing of components of an automobile (ref the above picture for the various components ), the component is put to a thorough inspection process for identifying defects such as cracks, assembly, poor seals, or poor fits. To avoid potential problems from occurring, manufacturers are seeking methods to streamline the quality checking process.

This may involve automated monitoring and assembly systems for testing the manufactured components, answer to this is LEAK TESTING– Checking for leaks is one of the popular methods used by manufacturers to identify machining errors and defective components.

Leak testing is a non-destructive method to identify leaks in an automobile component and an important component of the quality control process. The leak test is carried out by sealing any ports or holes the test component might have and introducing a test medium into or around the test piece. The medium is usually air, nitrogen or helium depending on the particular application situation on which leak is being tested. They can do a wide range of tests. When these leak testing machines are used correctly in the manufacturing process, it can bring following considerable benefits to the manufacturers.

- Reduced Cost and Waste

Leak testing not only leads to accuracy and reliability but also significantly helps in improving the efficiency of the production line and reducing repair costs and warranty claims. When the manufactured components are reliably tested in the factory, it prevents defective components from being sent out to the customer. This avoids component recalls against a faulty component as well as prevents warranty claims and stained reputation which can incur a financial loss to the company.

In the assembly, leak testing can also be effectively used before the assembly process to improve efficiency and productivity. If the components have been properly tested for leakages and blockages before the assembly process, manufacturers can avoid restarting the entire assembly process which may occur if defective components are used in the assembly.

- Ensuring High Component Quality

A leak test can validate the quality of the supplier’s component and test the reliability of the component. Many Automobile OEM suppliers conduct leak tests on their components before the assembly to ensure that only high-quality components are used in the assembly line. This minimizes the chance of leakage and defect in the finished, assembled component.

Often, the finished components are also subjected to leak testing before being packed and dispatched to customers as final validation. From the manufacturer’s point of view, having a consistent leak testing process for each and every assembly stage will help them in performing the root causes analysis in case of components failure. This will eventually reduce the amounts of tests they need to do in order to identify the cause of failure.

- Customer Safety and Hazard Prevention

Leak testing is also commonly used for testing components that go in the manufacturing of the automobile. These components should be tested to absolute precision as they may have a huge impact on health and the environment. For example, even small defects in the brake system are not tolerable as its consequences can be fatal to life & danger to the surrounding environment should they fail.

- No False-Failures

During the leak testing of an automobile component, a consistent leak-tight connection and seal for all ports and holes is applied to the test piece, regardless of the test method. The objective of providing this tight connection is to isolate the component for testing, which can only be accomplished when all of the test ports and holes are sealed and leak-tight. By creating a leak-tight seal, chances of detecting a false failure are reduced, which is caused by an improper connection or seal, which allows media to seep into or out of the test component.

There are various tools engineered to be used as a quick connection tool designed to create a repeatable leak-tight connection to a specific port, thread, tube, or hole. These tools are available for different types of leak testing processes, whether manual, semi-automated or fully automated, allowing users to safely make the necessary connections to run a proper leak test without a concern

Modern leak testing devices use high-quality sensors and instrumentation as well as integrate with analytics platforms to facilitate process improvement in industrial manufacturing. As the concept of Industry 4.0 gets familiar with the automobile manufacturing industry, many manufacturers have started using leak testing data gathered in real-time to improve their manufacturing processes as a whole.

Choosing the right leak testing method & building the right machine is critically important & it all starts with your choice of leak test machine builder. they need an extremely high level of expertise, competencies & also need to understand your requirements. For knowledgeable advice & a genuine desire to provide a top-quality reliable, innovative and flexible solution connect with A B Process Technologies, Pune.

Thank you for sharing your valuable tips! This is very helpful and informative! We work for the same cause! Get in touch with us at +919004813456 or our website https://tekman.co.in/ .